MU-O Vario Range

4 Models | 1800–2500mm (71–98") | Up To 130hp

Description

Muthing mulchers are a premium range of flail mowers, designed and engineered in Germany. The Muthing Mulching System provides many benefits for groundcare management, including weed control, pest control, input cost reductions (fertilisers, pesticides and herbicides) and improvement in soil structure and fertility.

Muthing mulchers are not only better designed, but also provide a safer working environment by reducing the risk of thrown objects. Muthing mulchers up to a 3.2m width have undergone Independent Thrown Object Certification and comply with Thrown Object Testing ISO/WD 17101-2. This ensures better public safety when operating in public spaces or roadside – a crucial consideration for councils and their suppliers.

For full specifications and a better look at the MU-O Vario Range, please download the brochure.

Features

Five Reasons To Own A Muthing

- German engineering and quality at its best – manufactured in Europe.

- No windrows – finely mulched and de-fibered material is spread evenly behind roller.

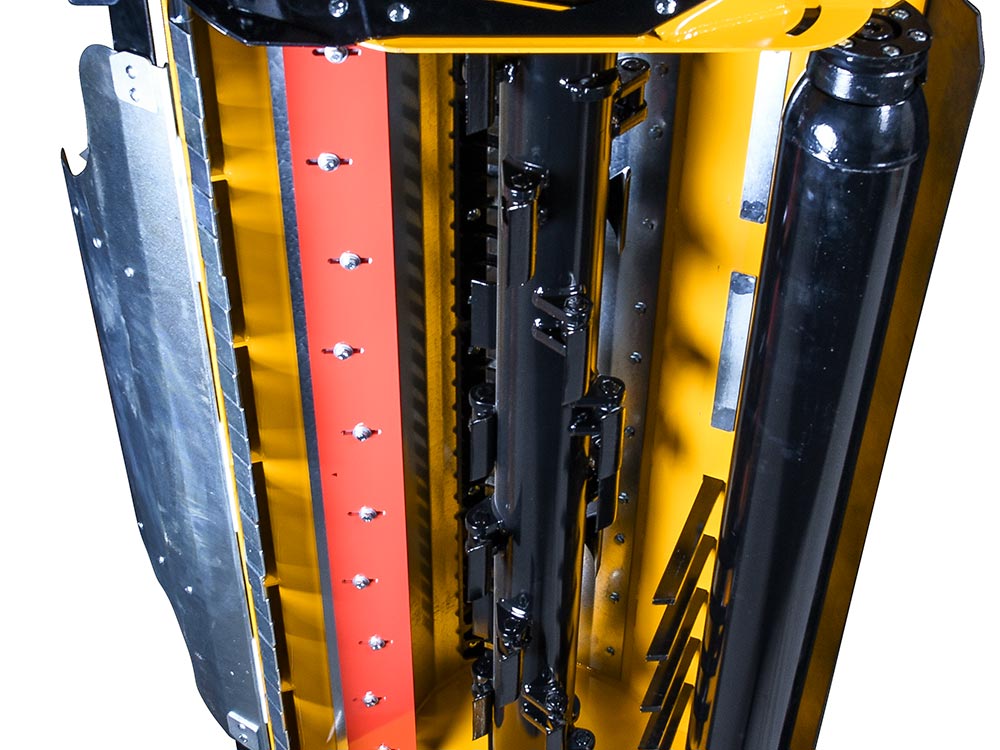

- Spiral Rotor with double forged ‘M Hammer’ Flails – the ultimate in reliability and longevity.

- Patented removable and segmented ‘Shark Fin’ shredding bars for a high quality shred and reduction in maintenance costs.

- Designed to be safer for vehicle traffic and passers by – Muthing mulchers have Thrown Object Certification.

MU-O Vario Standard Equipment

- The MU-O is designed for orchard or vineyard applications, and has a multi-position roller and pruning rakes. This machine facilitates very effective mulching practices in both pruning and grass or pasture management.

- Manufactured from High Quality QSt/E Steel with multi position headstock Cat. I + II for front and rear mounting

- Rear mounting with mechanical side shift; MU-O 180 – 250 Vario: 56 cm

- Gearbox with integrated over run clutch and through drive for 540 / 1.000 rpm

- Belt protection with tension measuring slot

- High tempered “M” Hammer flails to ensure clean cut and maximum shredding using less power

- Spiral Rotor with specially formed flail lugs to protect against damage from obstacles, bearings protected against dirt, wear and tear

- Patented removable shredding bar – System: “Shark fin”

- Support roller to carry the flail, adjustable for different heights of the mulching system, with “Starinth” Roller Bearing

- High tempered spring steel one way protection flaps in front of the mower hood

- Optimised distance between the outer rotor circle and the support roller guarantees perfect contour following and an even quality of cut

- Spreads the shredded material evenly behind the support roller

- Excellent Mulching Quality

- Side skids

- PTO shaft with hardened inner pipe and cap bottom lubrication

Optional Upgrades & Attachments

- Front and rear headstock Cat. I + II (shiftable or fixed mounted), support leg, central mounting

- Central mounting for MU-O 180 – 250 Vario

- Hydraulic side shift (1 double acting spool valve required) MU-O 180 – 250 Vario: 56 cm lifting range

- Front shock-absorbing spring assembly required

- Alternatively we recommend Hydraulic Weight Transfer MU-SOFA®

- Alternative flails and rotor systems (triple Y-blades, “M”-Shackle flails)

- Adjustable cutting bar (Vario)

- Hood Wear plate

- Carbide wearing skids, removable, incl. baffle plate

- Second patented removable shredding bar – System: “Shark fin”

- Operating hours counter with sensor, time recording via angular momentum

- Lighting equipment support bolted onto the 3-point trestle

Models

MU-O 180 Vario – 1800mm working width, 16 flails

MU-O 200 Vario – 2000mm working width, 16 flails

MU-O 220 Vario – 2200mm working width, 18 flails

MU-O 250 Vario – 2500mm working width, 22 flails

Distributor’s Website

Southern Cross Ag Machinery – www.sxm.com.au

Have a question about this product? Call or visit our stores or enquire online.